Currently, construction is widely used translucent materials to create architectural designs that shape the modern buildings. Along with mineral glass widespread monolithic polycarbonate, which has a higher strength, resistance to extreme temperatures and ease in comparison with glass. However, polycarbonates, like all organic polymers, when heated, decompose to combustible low-molecular components, which in turn can cause a fire. Given the high requirements for fire retardancy of polymeric materials, the creation of non-flammable grades of polycarbonate is the most urgent and relevant task.

To date, to reduce the Flammability of polymeric materials used functional additive flame retardants. For example, the additive 3M FR-2025 allows you to create compositions corresponding to the index V-0 according to UL-94 standard, but this is often not enough, because currently, polymeric building materials are subject to more stringent requirements. In particular, a category of combustibility G-1 according to GOST 30244-94 material needs not only to immediately fade when removed from the flame source, and not to form burning droplets, the appearance of which greatly reduces the effectiveness of flame retardants.

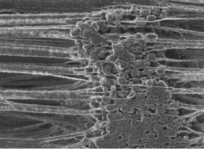

To solve this problem, the company 3M has developed a new antitipping additive Dynamar TF-2071-Z based on tetrafluoroethylene. The effect of additives based on the formation of a fibrillar mesh in combustion of the polymer, which enhances its melt and prevents the formation of burning droplets in contact with open flames. Additive TF-2071-z are effective when administered in the composition in amount of from 0.1 to 1.0 % together with flame retardants, which allows you to create material corresponding to the category G-1 according to GOST 30244-94. For maximum effect, the additive should be well dispersed in polymer matrix.

In some cases, as melt additives to cement as a filler used fiberglass, with the introduction of which up to 30% reduced the Flammability of the material due to the replacement of part of a polymer matrix of inert glass, thus reducing the number of degradation products (fuel) in the flame burning, but it should be noted that this will inevitably lead to increased brittleness of the material, as well as the loss of such important properties of polycarbonate products as the transmission. New additive Dynamar TF-2071-Z solves this problem, allowing you to greatly save on the high level of light transmission of polycarbonate products.

Properties Dynamar TF-2071-Z allows to apply additive not only in the polycarbonate, and other thermoplastics, the molding of thermoplastics, forming blown, the production of wires and cables, foamed products, and elastomers. Antitipping additives from 3M is widely established in the formulations of flame retardant polycarbonate largest European manufacturers.

_i.jpg/w161h45.jpg) We reduce the weight of power lines so they can carry more power to more people. We help manufacturers use less while accomplishing more. We automate health care data so the right people get the right information. Across the globe, 3M is inspiring innovation and igniting progress, all while contributing to true global sustainable development through environmental protection, corporate and social responsibility and economic progress.

We reduce the weight of power lines so they can carry more power to more people. We help manufacturers use less while accomplishing more. We automate health care data so the right people get the right information. Across the globe, 3M is inspiring innovation and igniting progress, all while contributing to true global sustainable development through environmental protection, corporate and social responsibility and economic progress.